TOFD - the emerging ultrasonic computerized

technique, for heavy wall Pressure Vessel welds examination

TOFD – 厚壁压力容器焊接检测超声成像计算机技术 (全文下载)

F. Betti, A. Guidi, B. Raffarta - NUM PIGNONE - Massa (Italy)

G.Nardoni, P. Nardoni, D. Nardoni - I&T Brescia (Italy)

L. Nottingham - Structural Integrity - U.S.A

Index

- Abstract

- Fundamentals of the TOFD technique

- TOFD norms

- TOFD Applications

- Physical principle of TOFD

- Configuration of system

- Scanning plan

- Scanning direction

- Real time acquisition and records

- Image evaluation

- Experiences on examination of welds

- Conclusions

- Bibliography

Abstract

The paper presents TOFD, the Time of Flight Diffraction Technique, currently the most promising ultrasonic technique for examination of heavy wall thickness welds on Pressure Vessels TOFD, is a computerized ultrasonic system, able to scan, store, and evaluate indications in terms of height (through thickness weld), length, position, with a degree of accuracy never achieved with other ultrasonic techniques. A record of examined sections is available in unprocessed form on floppy disk or CD and readable in Word for Windows 95. The ASME Code, with Code Case no. 2235 has accepted this method in lieu of radiography examination for thicknesses over 4 " (1). Experiences on 75 mm up to 300 mm thick welds of 2.5 / 3 % Q 1 Mo, 0.25 V and Carbon steel are discussed. The technique has been applied on longitudinal, circumferential and nozzle-shell/bead welds. Scanning Plan Data and its validation are reported with used test blocks. Cladded layers in TOFD images are presented. Based on experience to date, prospects for this new technique are of great interest.

New Non-destructive Examination

(TOFD SYSTEM)

| HIGHLY RELIABLE UT TECHNIQUE-----TOFD UT SYSTEM |

All the butt welds of high pressure vessels manufactured in accordance with ASME Sect. VIII.DIV.2 should be inspected by using RT for quality assurance. But recent ASME Code Case 2235 permits automatic UT in lieu of RT. Kobe Steel has developed the new automatic UT technique using TOFD (Time of Flight Diffraction) method and has been using for inspection of welds of heavy wall pressure vessels in lieu of RT.

<Features of TOFD>

- High Probability of Flaw Detection

- High Accuracy of Flaw Location Measurement

- High Accuracy of Flaw Sizing in Length

- Weld Integrity to be observed on CRT in Real Time as probes scan

- All inspection Data to be Digitised and Stored so that the Data can be Recalled and Processed for In-Service Inspection

<What is TOFD?>

The basic configuration for TOFD (Time Of Flight Diffraction) technique consists of a separate ultrasonic transmitter and receiver. After emission of a compressional wave from a transmitter, the first signal to arrive at the receiver is lateral wave through upper surface. In the absence of defects the second signal to arrive at the receiver is the backwall echo. The diffracted signal generated at the upper tip of a defect will arrive before the signal generated at the lower tip of a defect.

With a time of flight of each flight path, the ultrasonic velocity and the spatial relationships of the two probes, location and height of defects can be very accurately calculated.

Gray scale imaging techniques are applied to the RF(AC) signal phases and enable weld integrity to be observed in real time. The defects are shown like as shell pattern on CRT. A-scan signals are stored in the memory together with location signals.

| TOFD System |

|

TOFD system consists of computerized UT detector, transmitter, receiver, pream-plifier, encoder and cables.

TOFD system is small and light and is portable and accessible to inspection position.

|

|

| Scanning and display on CRT |

|

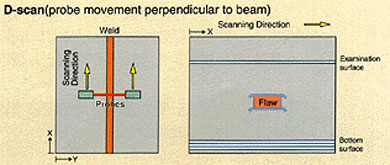

D-Scan

D-scan is non parallel scanning placing weldment at the center of the two probes.

Signals from the upper and lower tips of a defect are displayed on gray scale.

D-scan and length and height of a defect can be accurately measured. D-scan is the most popular scanning procedure for weldment.

|

|

|

|

Sonovision是坚固、可携式的超音波检测系统,能够同时做多频道的Time-of-Flight-Diffraction (TOFD) 以及脉冲回波 Pulse Echo (PE) 的腐蚀/侵蚀的内部扫描到大范围的单一/多轴控制器,包含影像追踪。本系统与各种的数据收集兼容并且能够在Windows 95/98/ME/NT/2000/XP离线数据分析软件内作业。

主要特色

l 膝上型可携带的完整厢型系统。

l 1, 2, 4, 8 或16 可转换频道

l 整合成单卡方案包含整个超音波脉器/接收器/digitiser & DSP

l 实时射频, A, B, C, D-scan 显示以及储存

l 多频道, 同步TOFD 以及脉冲回波 Pulse Echo 腐蚀/侵蚀图像能力

l Position stamping from up to 2 encoders

l 使用影像追踪技术做腐蚀扫描

l 完整的表面配置,数据取得, 离线分析以及做报告软件

l Windows 95/98/ME/NT/2000/XP 操作系统

l 利用daisy-chaining额外的卡最多可扩充到256 频道·

l 外部或是内部马达趋动选项

l 电池作业时间长达2-4 小时或是利用扩充的电池选项可以延长到6-8小时

持续的软硬件更新以及改善

|

个人计算机规格

|

|

|

一般

|

|

实体

|

|

处理器

|

Pentium Centrino 1.4/1.6GHz

|

外部体积

|

310Wx254Dx121Hmm

(12.2"x10.0"x4.7")

|

|

内存

|

256MB DDR(可升级)

|

重量

|

6.5公斤(14lb)

|

|

硬盘

|

40GB(可升级)

|

温度范围

|

0o C到50o C

|

|

屏幕

|

14.1"XGA(1024x768)

在白天仍可以清楚看到屏幕的TFT(可升级)

|

|

电力

|

|

界面

|

2xRS232(可以选RS422/RS485),

EPP/ECP parallel,2xUSB, 10/100

以太网络

|

输入电压

|

100-240VAC(10-20V DC可选)

|

|

储存

|

1.44MB floppy,

CD-ROM(RW可选)

|

电池

|

作业下2-4小时

(外加电池可以扩充到6-8小时)

|

|

|

|

|

|

|

|

|

无损高温TOFD 检测

经过过去几年多次的现场测试经验,我们有丰富的使用TOFD做高温检测的经验。

用TOFD技术,温度差异的影响可以比较容易量化以及证实。

最初的研发工作是在几年以前,一个工程师在检测200度高温的蒸气锅炉时由客户以及Stoomwezen (荷兰籍的检测人员)发展出来,这个技术后来用在设定间隔的的非破坏检测上。

直到最近在温度的信度上才有很大的进展。Sonovation 缩短了工作中的焊接检测(在高过摄氏400度的化学反应槽外壳),一再的证实TOFD侦测技术以及在高达摄氏450度量测缺陷尺寸确实可靠!!

|

|

|

|

证实可以运用高温焊接检测

Sonovation 一再的在高达摄氏435度的焊接表面完成检测。TOFD 检测包含在化学反应器的焊接、连到240公厘到180公厘壁厚的圆顶。

这个挑战的复杂度包含了几何学以及Sonovation团队在现场所要克服的高温工作状况。不断的密切的与客户合作、热情以及专业的Sonovation团队证实能够带给客户更具创造性的解决方案。

|

|

|

Sonovation 主要的客户范围

化学、石化、炼油、气体开采以及生产行业

Sonovation 主要提供的服务

-TOFD ( Time of Flight Diffraction)

-项控数组 Phased Array

-C-scan 腐蚀扫描

-长距离超音波 Long Range UT (腐蚀检测/扫描)

-管道扫描系统

-脉冲涡电流 (腐蚀监控/检测)

-

传统的超音波(焊接检测)

-MT

-PT

-顾问

特定应用

-复杂几何

-高温

-

-

非标准化材料热氢害

长距离超音波

|